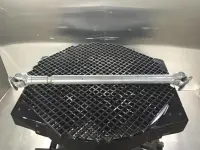

Liebherr Undercarriage

Used Liebherr undercarriage

The undercarriage of a Liebherr excavator is the foundation of an excavator and provides mobility and stability for the machine. The choice of undercarriage depends on the surface where the excavator will be used. For greater maneuverability, a mobile undercarriage is the best option; for rough terrain, a crawler undercarriage is more suitable.

Mobile undercarriage

A mobile undercarriage is suitable for excavators that need to travel frequently over paved surfaces, such as a waste processor or scrap dealer. A mobile undercarriage uses wheels and tires for this purpose. These are also the parts that wear out the fastest on a mobile undercarriage.

Solid rubber tire

Solid rubber tires are made of solid rubber and therefore never go flat. These tires are used on excavators that operate in areas where sharp objects are on the ground, such as at a landfill. The disadvantage of these solid tires is their weight and lack of suspension. In addition, they are not allowed on public roads. There is little that can go wrong with a solid rubber tire, except that over time chunks and cracks may appear in the rubber.

Pneumatic tire

Pneumatic tires for excavators are a lightweight solution and therefore offer much more mobility than solid rubber tires. Not only is the weight lower, but the comfort is also better because the tires provide more suspension. In addition, an excavator with pneumatic tires is allowed on public roads. The disadvantage of these tires is that they can go flat.

Crawler undercarriage

With a crawler undercarriage, an excavator can traverse difficult-to-access or rough terrain. Tracks provide more contact with the ground, resulting in increased grip, preventing the excavator from sinking, and distributing the weight of the excavator to avoid soil compaction. For uneven terrain, muddy surfaces, or steep slopes, tracks are therefore indispensable. The components of tracks are made of solid steel, and the excavator sits lower than with rubber tires. Due to the very low center of gravity, there is a lot of stability, allowing the excavator to lift and pull more. A crawler undercarriage consists of the following components:

Wear on a Liebherr undercarriage

Although the parts are made of solid steel, they still wear out over time. The undercarriage, chains, links, and guides often become loose due to wear. The springs of the rollers usually break, causing the chain to lose tension. Chains and plates are parts that wear out relatively quickly. The chains must be round. Over time, due to wear, they become oval. This is the moment to replace them. Because they are made entirely of steel, used parts are a good alternative to the often expensive new parts.

Undercarriage parts

In addition to tracks and rubber tires, other used components are also available for the undercarriage of an excavator. For example, extra legs can be attached to the undercarriage to provide the excavator with more stability when stationary. A blade can also be attached for additional earthmoving, protection, and increased stability.

Delivery of spare parts

We understand that you want to quickly replace a part of your machine when it is worn out. That is why we ensure that orders placed before 12:00 are shipped the next day.

Prices of parts

Buying used parts for an undercarriage has many advantages. We have many parts in stock. We probably also have the part you are looking for ready for you. The price is also a major advantage. You pay up to 60% less than the new price. And, as you are used to from us, the used part is of the highest quality.